The roasting traditions of Bairds Malt can be traced back to the 1800s, when the Baird brothers set up as maltsters in Glasgow before expanding their operations into the south of England. In 1925, Hugh Baird purchased the Witham malting site in Essex, in the heart of the ‘granary of England’ and a prime area for growing barley in the UK. Originally a floor maltings, it underwent an extensive refurbishment in the 1960’s. In operation now for over sixty years, Bairds’ Witham Roast House has been a leading supplier of roasted malt to the brewing industry worldwide. Although times have changed since its opening, the underlying roasting process and the company’s passion for creating a quality product remains the same.

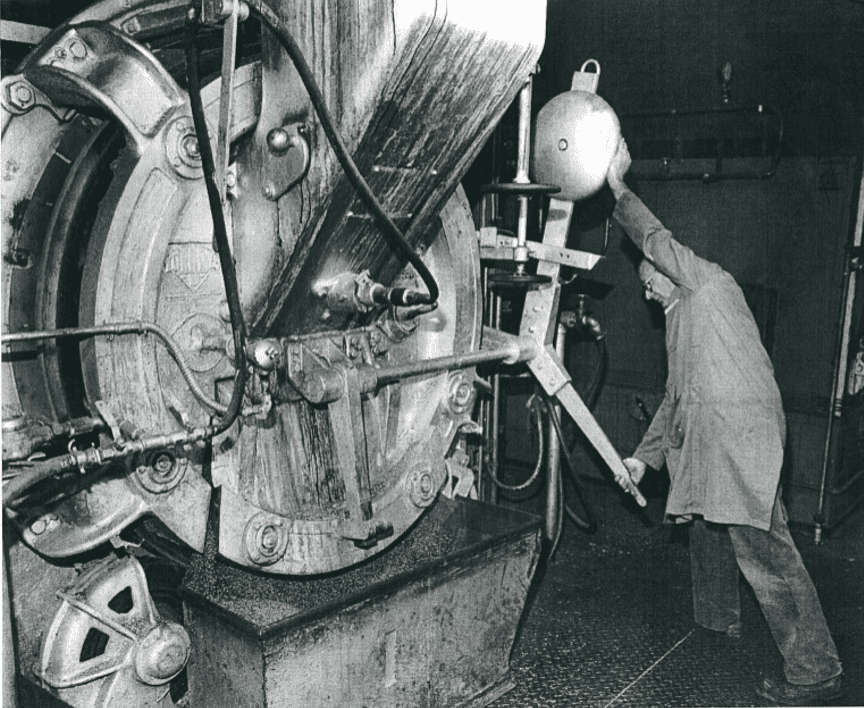

The Witham Roast House was established in 1962, and originally contained two G.W. Barth machines, known as Roaster 1 and Roaster 2 – or, more commonly, ‘Annie’ and ‘Bessie’ by the operators of the time. These machines were old coffee roasters which were small in size and very basic compared to what we know and use today, with a one-tonne batch size and operated manually. Below is a picture from the 1980s which shows the foreman of the time, Ken Mallison, discharging the roasting drum by hand into the cooler below.

1987 saw the removal of what was Roaster 3, a small half-tonne machine, and the arrival of the new Roaster 3, which can be seen in the background. The brand new Probat machine was a significant upgrade in terms of size and technology and is still going strong today, some 33 years later. An anecdote from this time of transition is still well remembered: in preparation for the arrival of the new roaster, the maintenance team had been instructed to dismantle the old cast iron machine, which was no small task. Just as they had finished, the managing director came down and told them to put it back together again as he had found a buyer; it’s easy to imagine they were not impressed! The old Roaster 3 and cooler can be seen in the picture below. Here, the operator is checking the temperature of the grain before discharging to its storage location.

In 1989, the Roast House underwent expansion to include the arrival of a new machine, Roaster 4, which was another large upgrade in technology and production capacity for Bairds. Bob Groom, who was the foreman at the time and still works in the Roast House today, was sent on his first flight abroad to Ludwigsberg, Germany, to inspect the machine. Roaster 4, which is still in operation today, can produce batches over two tonnes in size. Utilizing an afterburner, this machine can eliminate the strong smells created when producing the highest colour products, such as black malt and roast barley. This was a great advancement and saw the decommissioning of the original two roasters which lacked the same ability. Bairds Malt was now an established presence in Witham, with the significant positioning of the maltings in an increasingly busy town with new housing and a nearby railway station. In the picture below, Roaster 4 can be seen shortly after it was installed.

The connection between Bairds’ sites in both Scotland and England were to prove essential for the Roast House. The raw material which is used for making crystal and cara malts is a well-modified green malt, but at the time, the Witham Maltings did not have the capacity to supply enough green malt to keep up with the demand of the Roast House. However, Bairds maltings site in Pencaitland, near Edinburgh meant that every week they could produce twelve lorryloads of green malt, germinated specifically for roasting, which was sent down to Essex. The operators say that it was ideal for roasting, as it effectively stewed in the back of the lorry on the 400-mile journey down, which is actually the first stage of the making great crystal malt!

The 1990s saw a great increase of white malt production capacity at the Witham Maltings with the H-Plant expansion. In the early 2000s, the old Wanderhaufen style maltings at the site became dedicated to producing germinated barley solely for roasting, and has been doing so ever since. By this time, the Roast House had a production capacity of 8000 tonnes a year, supplying largely to the regional brewing market and distilling customers, as well as internationally to North America and Japan.

Since the turn of the century, and with the ever-increasing demand to improve health and safety standards, the Roast House has had to adapt to continue making products safely in what has always been a dangerous process. Heating grain to almost the point of combustion to create the desired product is not without risk, and consequently significant and continuous investment has been made to reduce the potential for harmful incidents. We are now lucky enough to have sophisticated control systems that monitor temperature and airflow, cutting-edge spark detection that constantly monitors and reacts within a split second and greatly improved dust extraction, to name a few.

Great advancements have also been made to the way we package and dispatch malt. Gone are the days when a team of eight workers would take three days to load a container with loose 25kg, 50kg and 75kg sacks that had been stitched by hand; it’s unlikely lifting 75kg sacks would fall in line with today’s manual handling standards. In 2019, Bairds moved to a purpose-built bagging warehouse, which has greatly improved the storage of packaged malt and reduced the labour-intensive manual stacking of pallets. Roasted malt is now packaged into 25kg easy-open sacks and automatically stacked onto pallets with a robotic palletising machine. There are now 35,000 tonnes of Barley storage available on site.

With the Bairds Malt Corporate Head Office now situated at the Witham malting site, the Roast House story continues to adapt and expand to meet the market needs in the 21st century; today, there are 14 different roasted malts produced at Witham. With roasting traditions dating back over 100 years, the Witham Roast House continues to be a leading supplier of roasted malts to markets worldwide. Bringing generations of experience and technical expertise together with continued investment into improving facilities, the Roast House will ensure it continues to meet the needs of its customers and commit to producing high quality roasted malts as safely as possible for years to come.