explore the malting process

our malts are all produced in the uk at our four malting sites located at the heart of the best growing areas along the eastern seaboard of the uk.

pre malting

At the heart of our quality malt is the UK’s best barley. Sourced from growers located close to our maltings and along the Eastern Seaboard of the UK.

-

Sown

Our long-term partnerships with growers allow us to ensure that a quality malt can be assured by a quality barley crop from the very outset. Our ongoing investment in trial plots each year also allows us the opportunity to bring forward new barley varieties, benefitting the grower, maltster and customer.

-

Grown

Many of our growers are second and third generation growers who have been supplying Bairds Malt for generations. Our merchanting divisions support growers pre crops being sown, and ensure a guaranteed purchase of grain post harvest – allowing the grower to have full confidence and devotion to concentrate on the growth of the barley.

-

Harvested

Our distribution of sites throughout the UK allow us to intake barley from growers without delay. Our on site analysis will provide each grower with a detailed breakdown of their crop, ensuring only the very best Barley is put forward for malt production.

-

Analysis

The barley arrives on the weighbridge at each of our maltings. During harvest time a pre-delivery sample is supplied so we only call forward barley that meets our specifications. Our barley is sampled and tested on the way into our sites, just as our malt is sampled and tested on the way out.

at the maltings

At the heart of our quality malt is the UK’s best barley. Sourced from growers located close to our maltings and along the Eastern Seaboard of the UK.

-

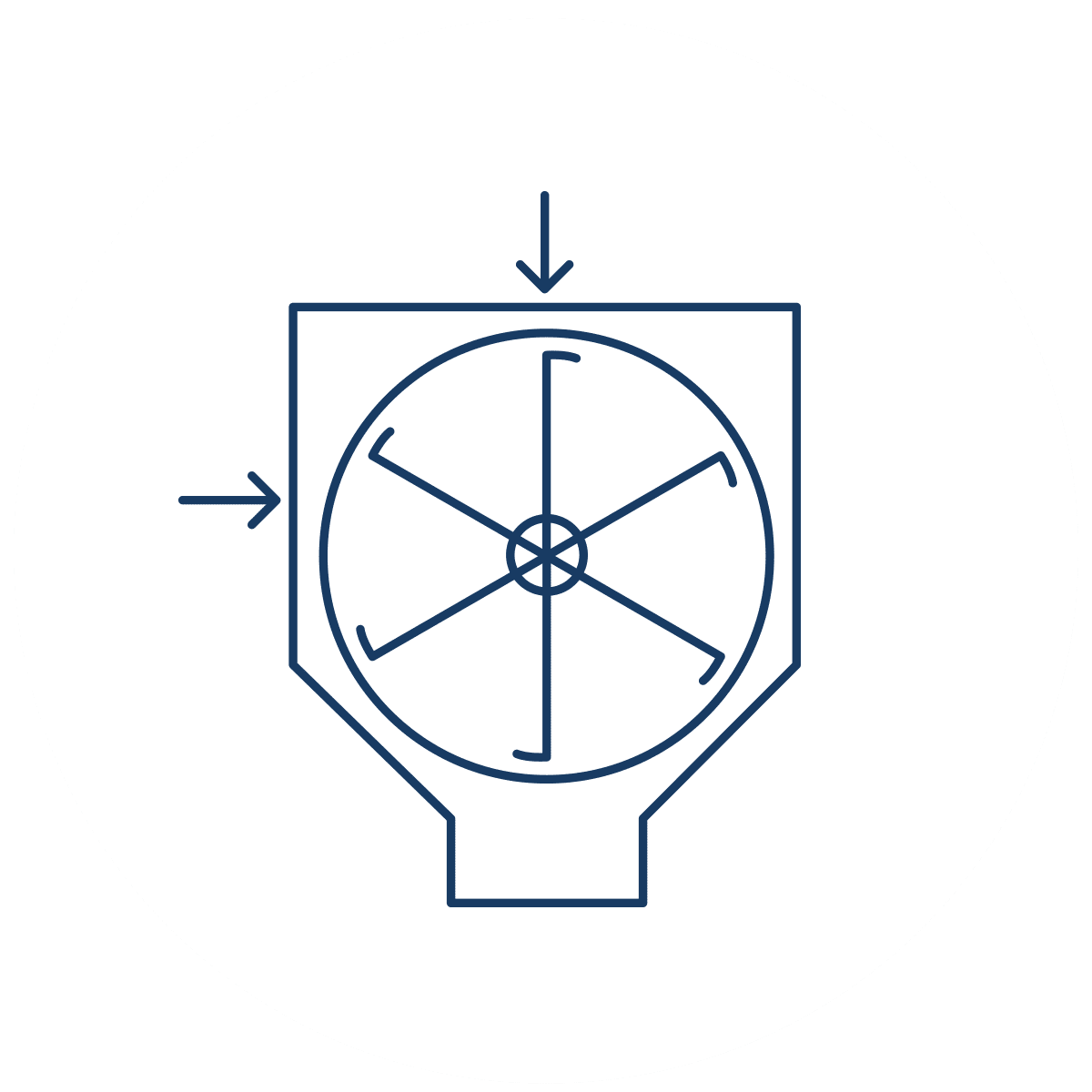

Drying (scotland)

As we have 4 intake points in Scotland we’re able to provide a home for local barley growers who need their freshly harvested barley moved quickly due to such high moisture levels. Barley from farms at harvest time can range in moisture from 18-25%, so it is important to dry this quickly and correctly for safe storage.

-

Cleaning and sorting

It is important to clean all barley prior to the malting process so that we ensure grains are homogeneous in size and that we don’t carry any chaff through to the malting process. We call the by-product of this process “light barley” which can be sold to manufacturers who turn this into animal feed.

-

STORING

Once we have dried the barley down to 12% moisture the grain can be safely stored in either bins or large flat stores. As we have to move such significant volumes over the harvest window we utilise large on site storage.

-

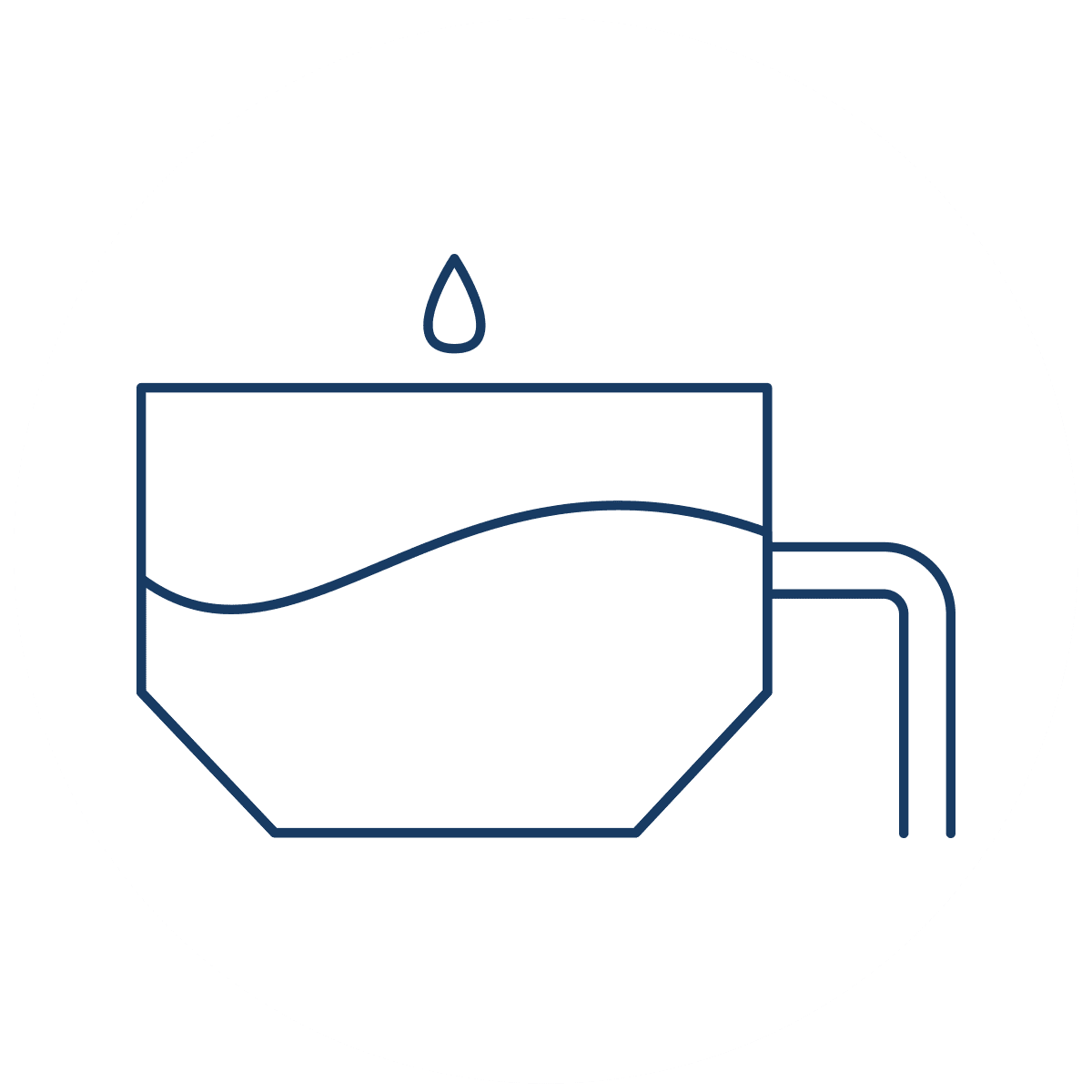

Steeping

Steeping is the first stage of the malting process and usually takes 1 to 2 days in total. The moisture content of the barley is raised from typically 12-13% to 42-45%. This is achieved by a series of immersions or wet cycles followed by dry periods. The grain becomes hydrated and starts to germinate.

-

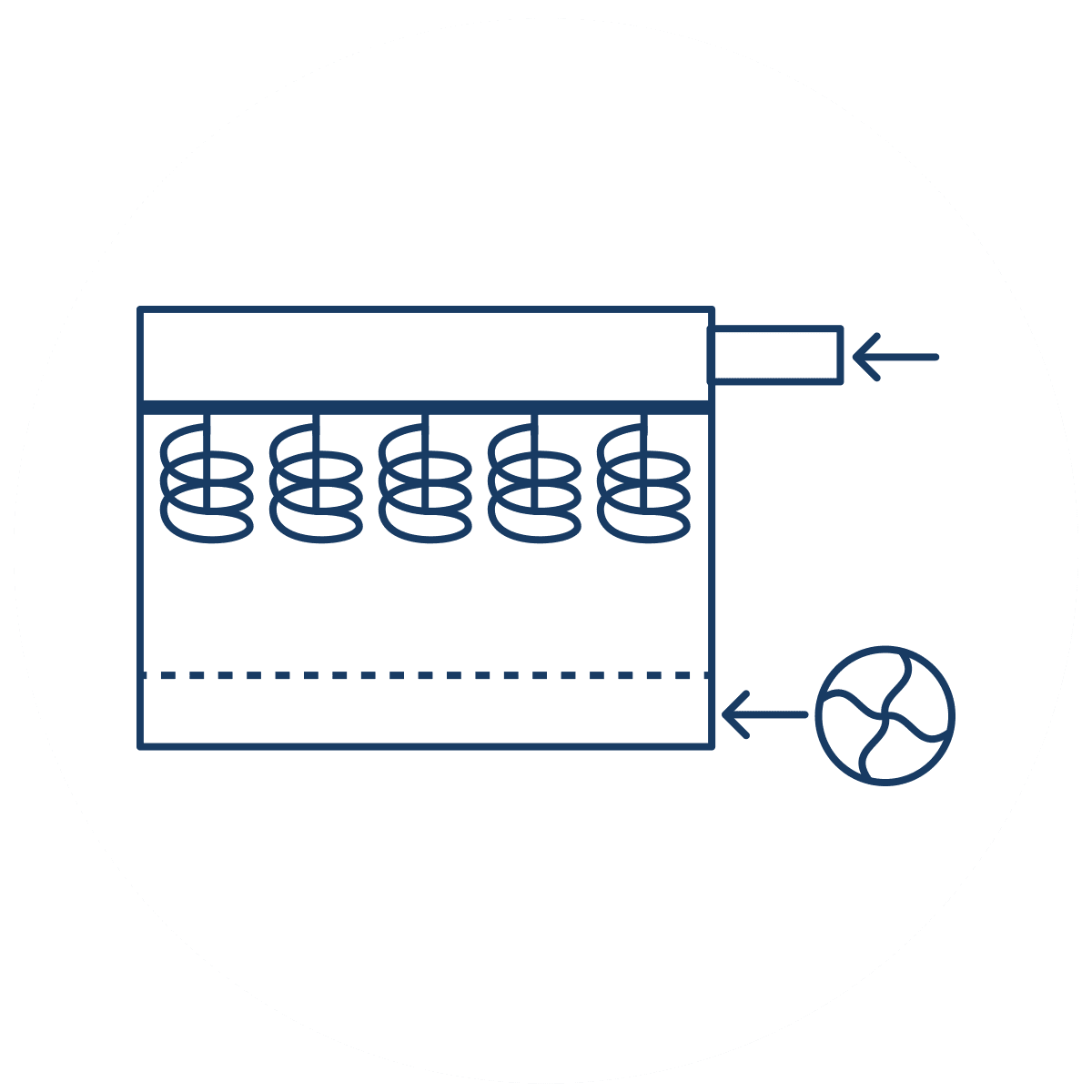

Germination

Barley has to grow evenly during the malting process to ensure high quality malt. Dead or dormant corns cause problems; they do not produce any usable extract (or spirit yield for distilling), and they can impair the quality of the finished malt. The germination phase is the ‘control’ phase of malting. Germination continues for a further 3-5 days depending on the product type being made.

-

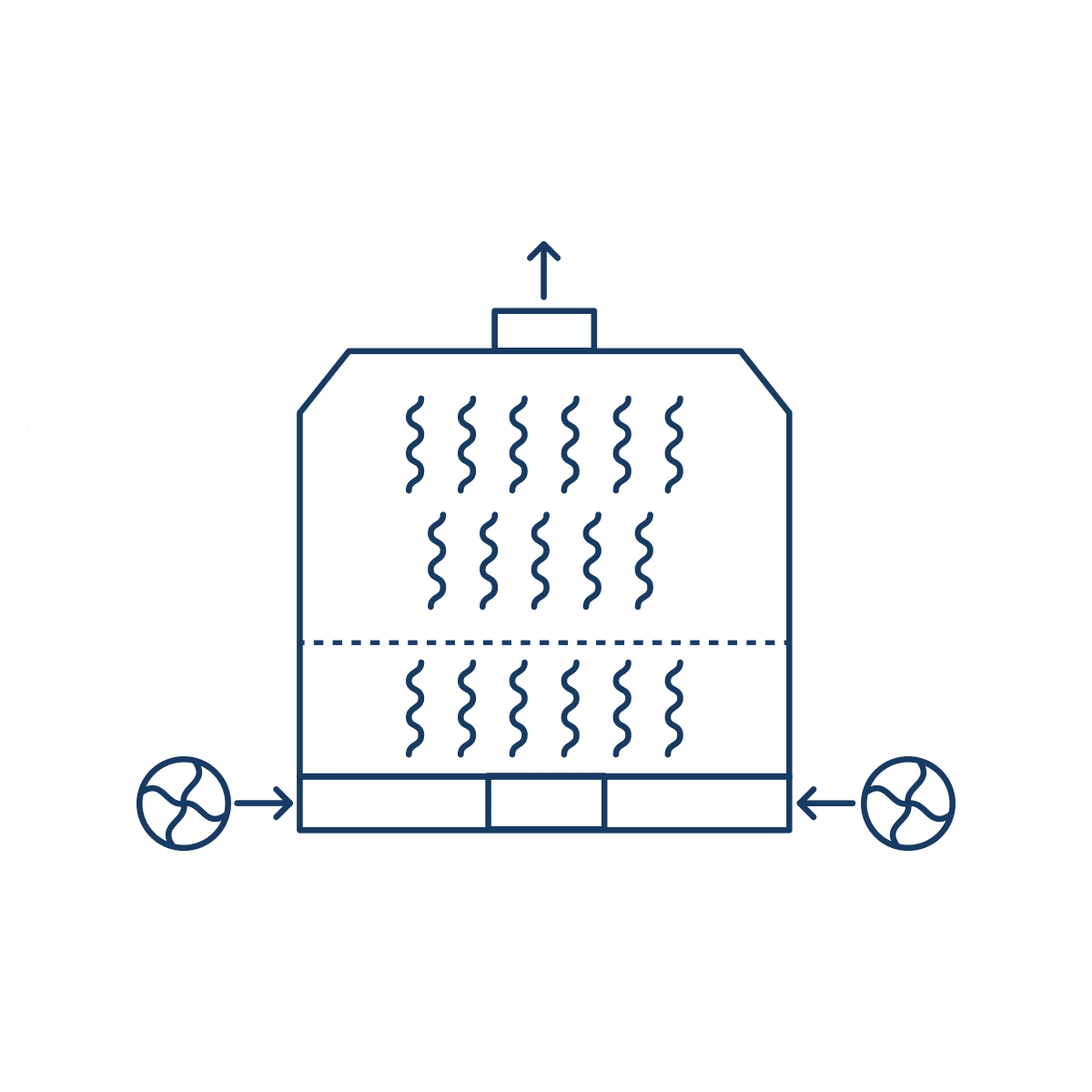

Kilning

Kilning, the third phase of malting, dries the grain down to 3-6% moisture. This arrests the biochemical processes occurring within the grain during germination and ensures a safe moisture content for storage.

Large volumes of hot air are blown through the grain bed to dry the grain while a predetermined temperature profile is applied. By varying air flow and the temperature profile, malts of different colours can be produced with varying flavour profiles.

At the end of kilning the malt is cooled and the tiny rootlets or culm removed before analysis and storage. The final malt is analysed extensively according to malt type and customer profile.

The malt may be despatched in bulk, bags or in containers.

roasted malts

Rather than being kilned, our Roasted Malts are dried in one of two roasting drums in our Witham Roast House.

peated malts

Peated malt is produced from conventional 2-row spring pot still malt which has peat reek introduced for several days during the kilning stage. Historically, this would have taken place as peat would have been burned to fire the kilns in parts of Scotland. The malts produced today have characteristic peaty flavours and aromas originating from the phenolic compounds imparted by the peat reek.

The malting boxes are germinated as normal until close to full modification is reached. The boxes are then kilned close to the break point before peat is added to a peat fire where it is lit and the peat encouraged to smoulder. The smoke or reek is passed through the malt bed transferring phenolic compound onto the malt. The peat fire is burned for up to 60 hours and once the fire is burned down the box is returned to the kilning phase to be dried down to approximately 4% moisture.

-

de culming

After the barley has been dried the malt is cleaned again to remove any rootlets that were formed during the germination process. The by-product of this cleaning and sorting process is pelletised and sold as animal feed through a 3rd party merchant. Malt from the kiln is put through a machine known as a deculmer, to remove the ‘culm’ or small rootlets that have emerged from each kernel during germination. Malt culm is a co-product for the maltster, which can be sold as an animal feed, as it has a higher protein content by weight than the original barley.

-

Resting

The malt is allowed to rest for a period of at least 2 weeks. This allows the grain to dry evenly to provide our customers with a more consistent product.

-

Analysis

Each batch of malt is further analysed prior to despatch to ensure it meets the specific needs of each customer.

-

Delivery

We can provide malt bagged or in bulk. Bagged malt is available in 25kg, 500kg, or 1000kg bags. Delivery to customers is normally available within an 24-72 hour period, either directly from our maltings, or from our distribution partners.

Follow us on the next stage of our story

THE BARLEY FORECAST

Join our subscriber list to be the first to learn our news.