Peated Malt

Peated malt is a speciality product predominantly used by Distillers to produce peated whisky, although it can also be used by Brewers to produce beers with smoky character. Bairds peated malt is solely produced at our Inverness maltings in the Highland capital with barley sourced from local growers. With close proximity to the port, our distilling malts make their way to serve both the domestic and international markets.

Bairds produce a range of 3 peated malts, ranging from our lightly peated distilling malt though to heavily peated distilling malt. Our Peated Malts are produced in Plant 1 of our Inverness Maltings where the majority of our Organic and Toll Malts are also produced, with customers often making use of the peating process when requesting a malt specific to their custom requirements.

Built in 1968 the creatively named ‘Plant 1’ consists of 10 malting vessels producing 40 tons of high quality malt per batch. Plant 1 is a static plant with the vessels being quite unique and perhaps the only in the United Kingdom that can facilitate Steeping, Germination and Kilning without the need for transfer during production, this gentle process allows the production of high quality malts. The plant consists of ten vessels with seven used for the production of white malts, whilst the three remaining vessels produce the much sought after peated malt.

MINIMUM TIME SPENT IN PEATING

Each batch has a target moisture level of less than 5% total moisture.

MAXIMUM TIME SPENT IN PEATING

Peat

Peat is the accumulation of partially decayed vegetation or organic matter. It is unique to natural areas called Peatlands, Bogs or sometimes Moors. Much of Scotland’s rural areas are Peatlands, and for many centuries peat has been used as a fuel which has been cut from the local bogs, dried out and burned to produce heat. Historically this was the case for many Scottish malting sites who used the peat as a kilning fuel prior to the introduction of coal and coke, the smoke passed through the malt bed as it was kilned resulting in smoky peated malt. Modern kilns are no longer fired using peat, they are predominantly gas fired with peated malt being produced in specially adapted kilns serviced by a peat fire to introduce the smoke to the airstream. The burning peat creates reek that is passed through the malt bed imparting phenolic compounds such as Phenol, Cresol, Eugenol and Guaiacol. This gives malt the smoky taste and smell we associate with peated malt and in turn peated Whisky. The peatiness of the malt is quantified by Phenols in (ppm) parts per million, lightly peated is up to 15, medium peated malt is 15-39 and heavily peated is 40+ Phenols.

the malt peating process

Our Peated Malts are made exclusively at our Inverness Maltings in the Heart of the Scottish Highlands.

Our Peat is sourced in accordance with the sustainability principles and practices of Scotch Whisky Association Peat Action Plan.

-

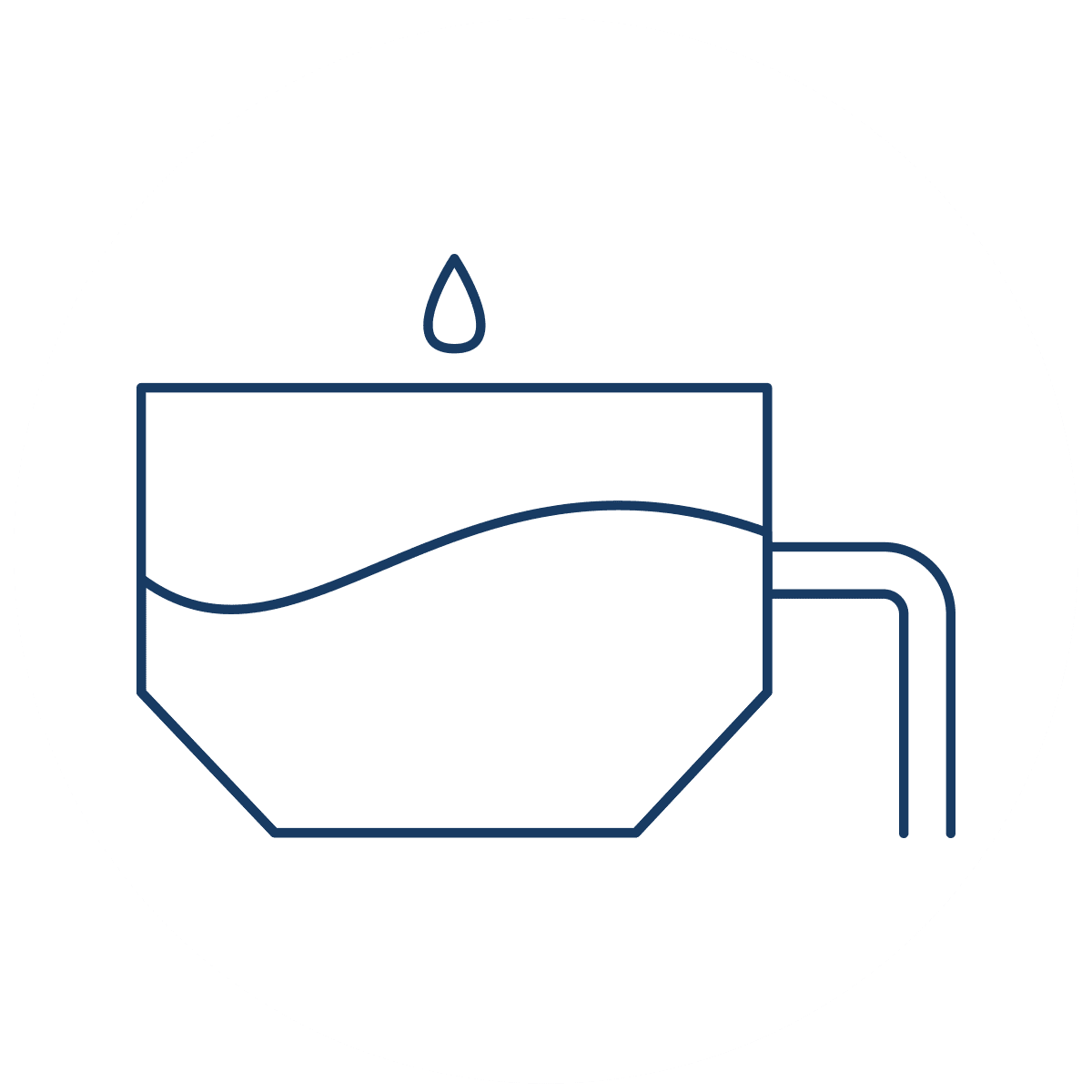

Steeping

Carefully selected low Nitrogen Highland barley is submerged in steep water, utilisation of multiple steeps and air breaks raise the grain moisture content to between 45 – 47%. During the Germination phase the grains can be seen to physically grow, this phase continues for between 72 to 84 hours.

-

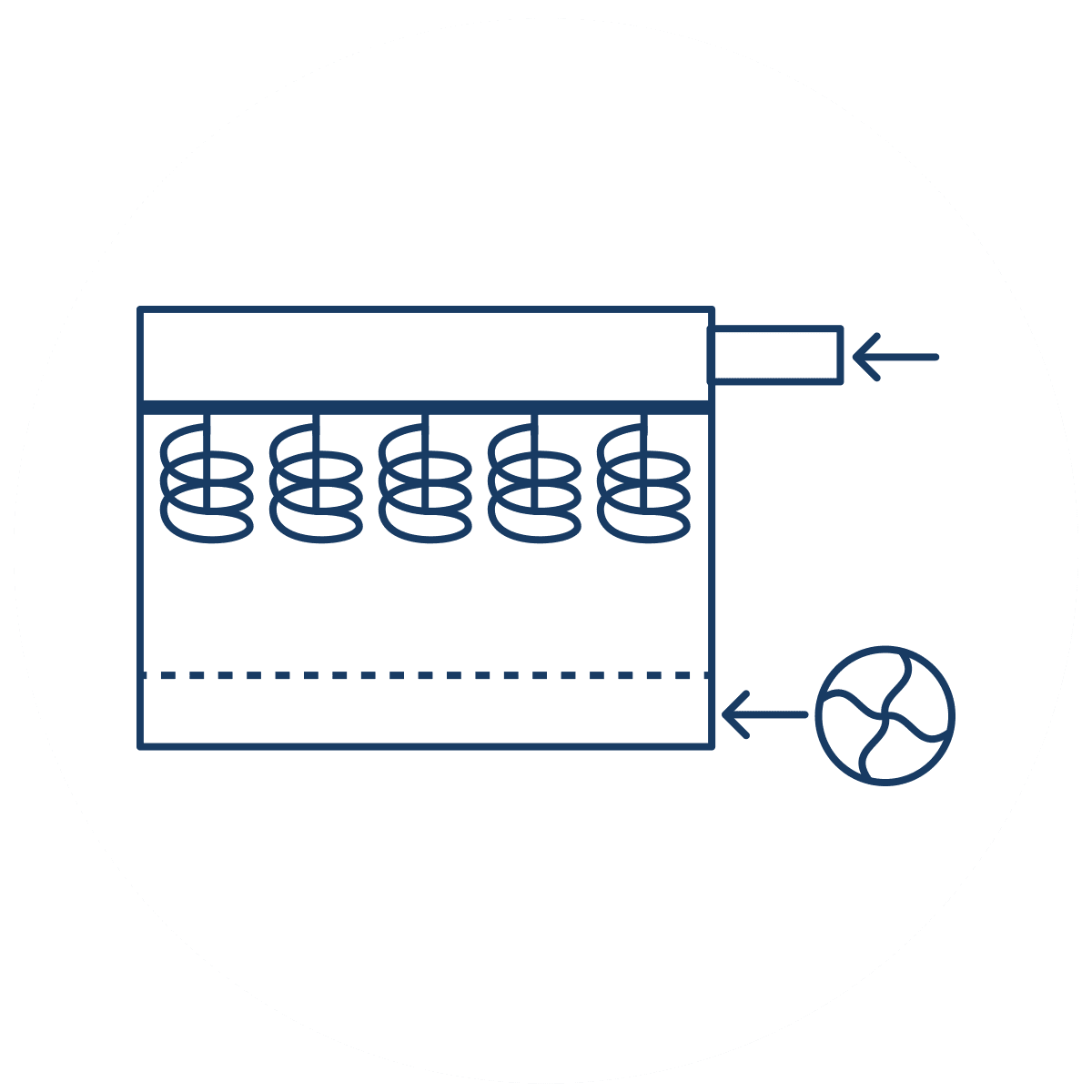

Germination

Humidified air is then passed through the grain bed with grain bed temperatures controlled until full endosperm modification is achieved. The malt beds are regularly turned to prevent matting and hotspots. Turning all 10 boxes in plant 1 is completed by one turning machine with helical screws, this is quite a feat with doors being raised and detachable rails connected for vessel entry.

-

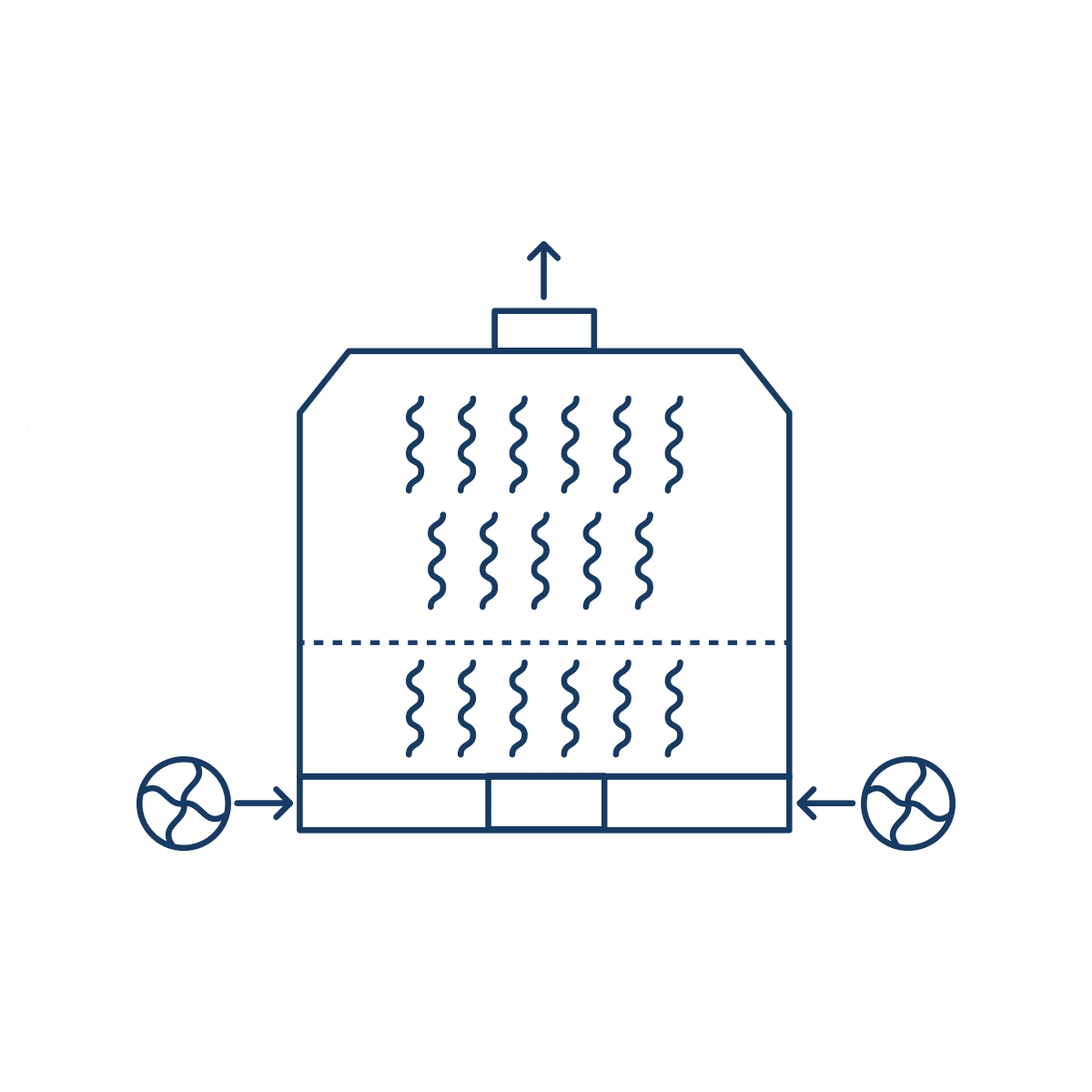

Kilning

Having raised the moisture content of the grains we must now remove a portion of it, this will give us the optimal conditions for the addition of peat reek to impart its magic to the grain bed. The process for moisture removal is known as Kilning. At the optimal point of Kilning the reek is introduced into the airstream. The reek is created by smoldering peat in a specially adapted fire. The peating process is carefully monitored by operators who ensure flaming of the fire does not occur by raking and adding peat. The use of peats from different geographical areas can offer differing Phenol profiles in the final malt. Between 48 and 84 hour of reek is passed through the grain bed, the fire is then burned out and the grain bed is dried down using a gentle Kilning profile until the target moisture of less than 5% is achieved.

Bairds Peated Malts

Our collection of Peated Malts range from Lightly Peated Malt to Highly Peated Malt. We are also pleased to work with customers to produce a malt to a customers specification, often using peat supplied from the customers local area.

Lightly Peated Malt

Medium Peated Malt

Heavily Peated Malt